Economic Order Quantity

Hasan Nasir

Holding an optimum inventory level is vital for any business because there are disadvantages to overholding and underholding inventory. Holding excessive inventory results in increased costs. However, with a shortage of inventory, one cannot meet the customer demand on time.

Thus, any business aims to have just the right quantity of inventory.

But the question is, how to arrive at the optimum inventory level? Well, the concept of ‘Economic Order Quantity’ helps answer this.

Economic Order Quantity or EOQ refers to the optimum amount of inventory one should order. Companies use this concept in inventory management. It aims at minimizing the costs of inventory buying and holding. At the same time, it also aims to meet customer demand.

Ford W. Harris, a production engineer, designed the EOQ model in 1913. It is now applied extensively in various businesses.

How is the Economic Order Quantity calculated?

To calculate the optimum order quantity, the following formula is used:

EOQ = Square root of [(2*D*S) / H]

Here

D = Annual demand (in units)

S = Fixed cost per order and

H = Holding cost per unit per year

Let us understand this with the help of an example:

Say company X is in the business of selling hats. It sells 10,000 hats each year. The fixed cost per order is $40. The cost of holding a hat for one year is $5. The cost per hat is $50.

How many hats should company X order?

As per the formula, the calculation of the EOQ is below:

EOQ = Square root of [(2 * 10000 hats* $40 fixed cost per order) / ($5 holding cost per saree)]

Thus, EOQ=400 hats

Thus, the optimum number of hats Company X should order is 400 at one time. This would help minimize costs and meet customer demand. If it orders any other quantity, the total cost will increase.

Let us see this by calculating the total cost of ordering 300, 400, and 500 hats.

Total cost = (Cost per hat * no. of hats) + (Fixed cost per order* no. of orders) + (avg. holding cost per hat)

Total cost for ordering 400 hats = $(50*10000) + (40* 10000/400) + (400*5/2)

= $5,02,000

If we calculate this amount for 300 hats, it comes to $5,02,083

If we calculate this amount for 500 hats, it comes to $5,02,050

Following are few factors on which the Economic Order Quantity calculation is based:

- EOQ assumes that one orders the same quantity each time.

- EOQ assumes that the time taken from placing the order to its delivery is constant.

- EOQ assumes that the cost of ordering is constant. This is even when the order quantity is changed.

- EOQ assumes that the demand from the customer remains constant throughout the year.

- EOQ assumes that there are no stockouts. This means one constantly monitors customer demand and inventory level.

Importance of Economic Order Quantity:

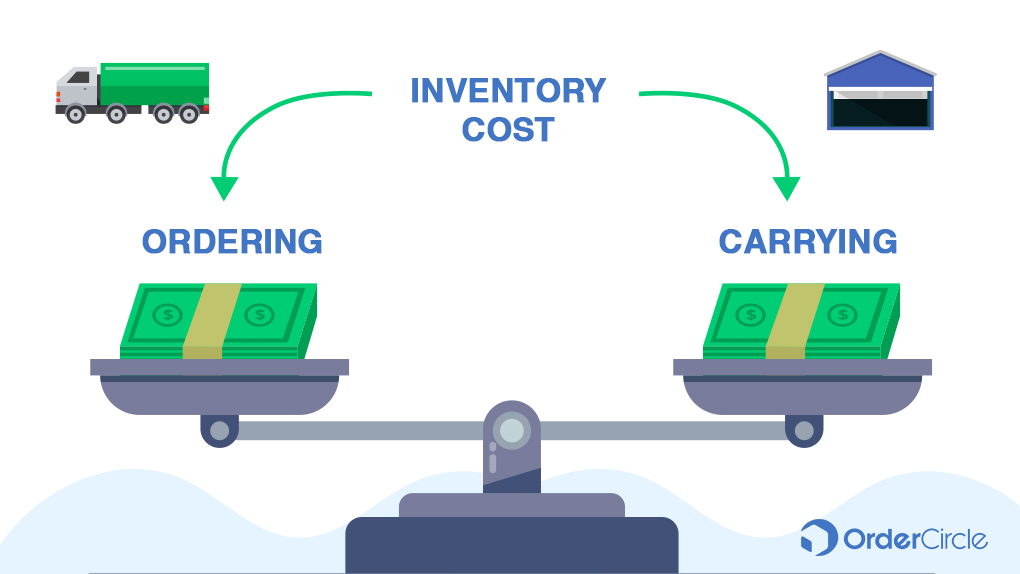

The Economic Order Quantity helps companies avoid overstocking or understocking their inventories. When the company orders more stock, the per-unit purchase cost decreases. However, on the other hand, the inventory holding cost increases. Thus, both these costs are inversely related to each other. And EOQ is the point that optimizes both these costs.

EOQ thus helps minimize costs and capital investments and increase profits. It also helps in faster decision-making. Thus, it helps in the smooth functioning of the supply chain.

Limitations of Economic Order Quantity (EOQ):

The EOQ formula gives us a fair idea of the right amount of inventory. However, it is based on some assumptions which may limit its use. EOQ assumes that consumer demand is constant. It also assumes that both inventory ordering and holding costs remain stable.

Thus, one might not be able to use it in all situations. It may be challenging to use EOQ when there are frequent changes in customer demand. It may also be difficult when there is a seasonal demand or changes in inventory costs.

EQQ also does not factor in the scope of bulk-buying of inventory. Sometimes, one might not have enough funds to place an order as per EOQ. Further, in the case of multiple products, one must make EOQ calculations for each product.

Conclusion:

Economic Order Quantity indicates an optimum order quantity. This helps in decision-making. It also helps in a smooth supply chain and cost minimization. However, EOQ is based on some assumptions and might not consider all the factors that affect a business. Thus, one must use it as per the business requirements. One can use it together with other methods to arrive at business decisions.